D day -1 all

clear waiting for the artisans to arrive.

About Me

- Pix Valley

- From Rugby, Warwickshire; Went to Marlborough Secondary School; Studied at Rugby College of Engineering Technology; Worked at HM Forces - British Army; Studied at Royal School of Military Engineering; Former Maintenance Technician at International Computers Limited; Former IT Support at GlaxoSmithKline Pharmaceuticals Ltd; Lives in Letchworth

Pages

Monday, 15 June 2015

Sunday, 29 March 2015

J72 chassis conversion for DCC Part 4

The replacement 3D printed muffs and gears proved to be out of gauge

for OO at 14.7 mm rather than 14.4 mm so I revered to the replacement Bachmann

set I ordered 3 sets of wheel spacers and 3 intermediate gears for a shade

under £10.

The

first loco wheel set was finished this morning and the chassis chipped as I type

its running in on the rolling road.

Tuesday, 24 March 2015

J72 chassis conversion for DCC Part 3

Today I completed

the first motor conversion

The replacement 3D printed muffs and gears arrived, not sure if they will do the job still it was worth a go!

Monday, 23 March 2015

J72 chassis conversion for DCC Part 2

As the

weather was quite pleasant the mill table was degreased and the vice set-up. One

set of chassis frames now milled

An 8mm hole not 5mm as first mentioned drilled where the motor brushes contact the frame. This was necessary to isolate the motor brushes from the frames.

There

is now ample room to fit the chip into its new pocket and even room for some

packing, and I have just received notification that my replacement 3D printed muffs

and gears or on there way via UPS, I’ll post how I get on with these when they

are fitted.

Saturday, 21 March 2015

Bachmann 32-500 BR Standard 5MT DCC fitting

Due to the numerous detailed fittings careful handing whilst removing the body is essential, starting with the rear left driving wheel remove the small slotted screw holding the speedo drive and gently ease away.

Moving forward to the front of the loco there is a cross headed screw under the bogie assembly that has to be removed

Moving forward to the front of the loco there is a cross headed screw under the bogie assembly that has to be removed

finally at the

rear again there is another cross headed screw under the brake rodding. I could

not find an easy way of removing all of the rodding so I unclipped the rear

actuator trunnion and nudged it a bit to access the screw.

Short countersunk is

the front and long cheese head the rear.

Having removed the body, it is a tight fit you

will see the blanking plug just forward of the gearbox, remove this and plug in

your decoder I used a Hatton’s standard 8 pin which fits into the plastic cradle

supplied.

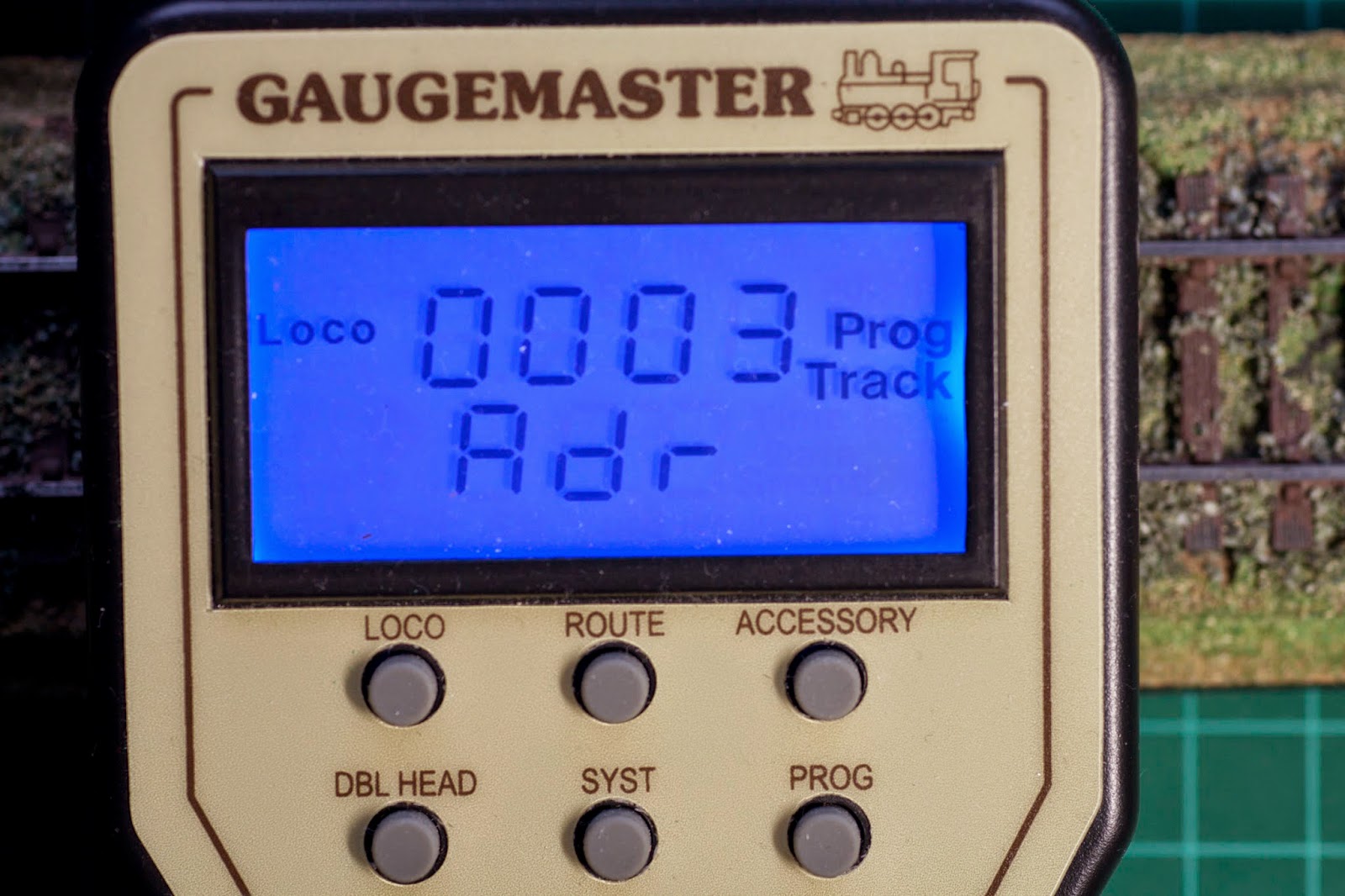

Before I reassembled the loco I performed a quick check on the programming track to see if I could read the chip.

Reassembly is of course done in reverse order;

check the body sits flush against the chassis you can see this from where the

screws fit not forgetting to locate plate that sits on the rear screw pillar

and the tender draw bar.

Gently tighten the two mounting screws checking the

alignment of the body as you go.

Sunday, 15 March 2015

J72 chassis conversion for DCC

J72 chassis conversion for DCC

One

of the sick J72’s has been stripped and degreased in my ultrasonic bath.

I

propose to remove around 2mm of material between the marks on the frames (lower

picture) the other side will be milled to the same profile and a 5mm hole drilled

where the motor brushes contact the frame. This will allow the chip to sit in

the boiler and the holes will allow the motor wires to exit the frames without

making contact. Unfortunately the weather has taken a turn so I will not be

degreasing the mill this week! As a foot note I have found another source of Replacement gear and

muffs for split-frame Bachmann J72 see

this link http://shpws.me/FD3X

Friday, 13 March 2015

Bachmann J72

Apparently this is quite common with split frame locos even

when they are stored!

Subscribe to:

Posts (Atom)